An encoder with 0.001° angular accuracy is a high-precision device used to measure rotational position or motion with extremely fine resolution. Such encoders are critical in applications where even the smallest angular deviation can significantly impact performance. Below is a detailed explanation of its features, applications, and considerations:

Key Features of a 0.001° Angular Accuracy Encoder

High Resolution:

The encoder can detect angular changes as small as 0.001°, which translates to 1/360,000 of a full rotation.

This level of precision is achieved through advanced optical, magnetic, or capacitive sensing technologies.

Low Error Margin:

The angular accuracy of 0.001° ensures minimal deviation from the true position, making it suitable for applications requiring ultra-high precision.

Repeatability:

The encoder can consistently return to the same position with minimal variation, ensuring reliable performance over time.

High-Speed Operation:

Despite its high precision, the encoder is often designed to operate at high rotational speeds without compromising accuracy.

Robust Construction:

Built to withstand harsh environments, including temperature fluctuations, vibrations, and contaminants, depending on the application.

Digital Output:

Typically provides digital signals (e.g., SSI, BiSS, or Ethernet-based protocols) for seamless integration with control systems.

Applications of a 0.001° Angular Accuracy Encoder

Aerospace and Defense:

Used in satellite positioning systems, radar antennas, and missile guidance systems where precise angular measurement is critical.

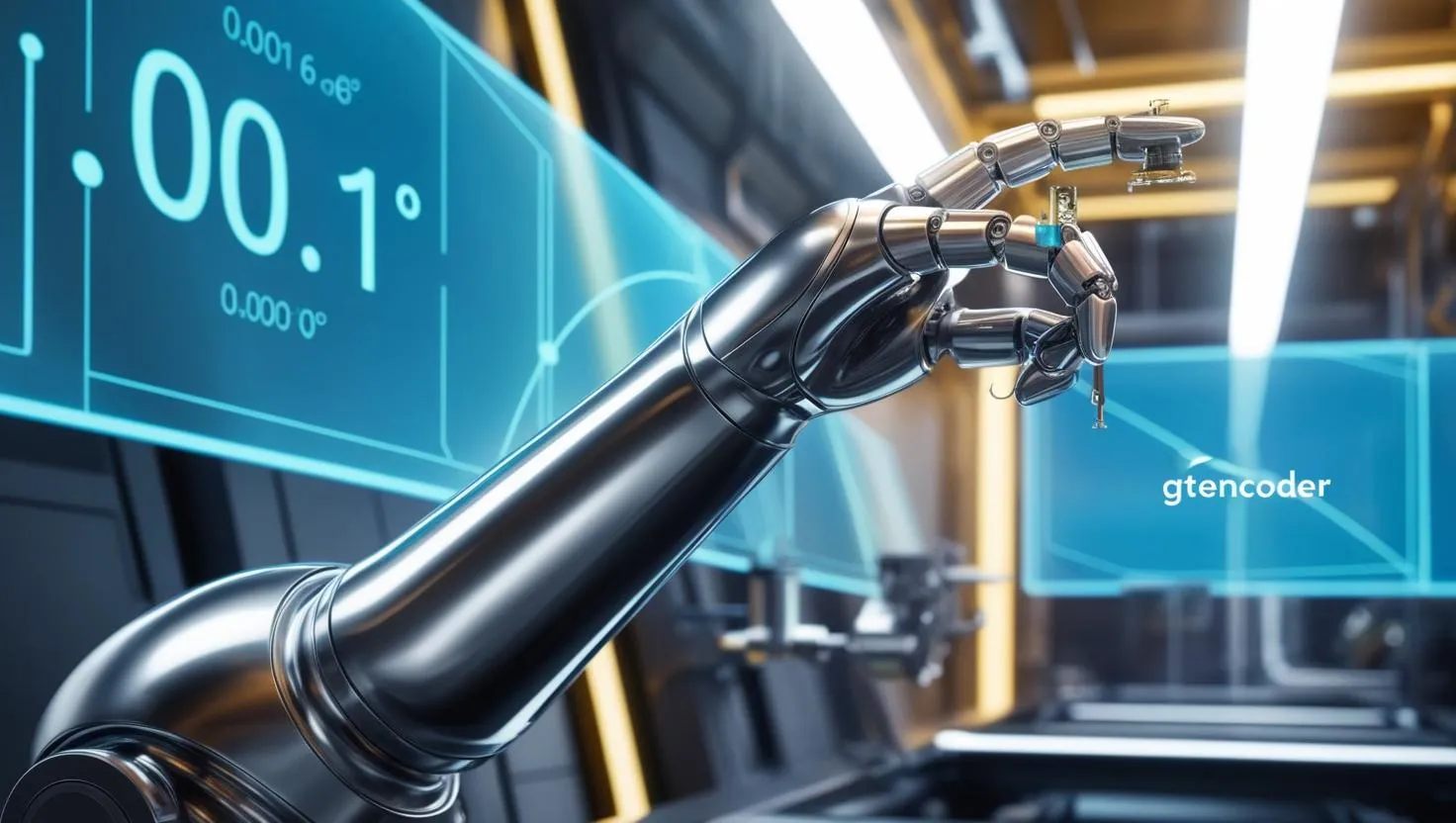

Robotics:

Enables high-precision motion control in industrial robots, surgical robots, and collaborative robots (cobots).

Semiconductor Manufacturing:

Essential for wafer handling, lithography, and inspection equipment where nanometer-level precision is required.

Medical Devices:

Used in imaging systems (e.g., CT scanners, MRI machines) and robotic surgical tools for accurate positioning.

Telescopes and Astronomy:

Ensures precise alignment and tracking of telescopes for celestial observations.

Industrial Automation:

Applied in CNC machines, rotary tables, and coordinate measuring machines (CMMs) for high-accuracy machining and inspection.

Energy Sector:

Used in wind turbine pitch control and solar tracking systems to optimize energy capture.

Considerations for Using a 0.001° Angular Accuracy Encoder

Cost:

High-precision encoders are expensive due to the advanced technology and materials required.

Installation:

Proper alignment and mounting are crucial to maintain accuracy. Misalignment can introduce errors.

Environmental Factors:

Temperature changes, vibrations, and dust can affect performance. Encoders with built-in compensation mechanisms are preferred for harsh environments.

Signal Processing:

High-resolution encoders generate large amounts of data, requiring robust signal processing and communication systems.

Maintenance:

Regular calibration and maintenance are necessary to ensure long-term accuracy and reliability.

Technologies Behind 0.001° Angular Accuracy

Optical Encoders:

Use a light source, photodetectors, and a high-resolution code disk to achieve ultra-fine angular measurements.

Magnetic Encoders:

Rely on magnetic fields and sensors to detect position changes. They are more robust in dirty or harsh environments.

Capacitive Encoders:

Measure changes in capacitance to determine angular position, offering high resolution and durability.

Laser-Based Encoders:

Utilize laser interferometry for extremely high precision, often used in scientific and metrology applications.

Future Trends

Integration with AI and IoT:

Encoders with 0.001° accuracy are increasingly being integrated into smart systems for predictive maintenance and real-time monitoring.

Miniaturization:

Development of smaller, more compact encoders without compromising precision.

Enhanced Durability:

Improved materials and designs to extend the lifespan of encoders in demanding environments.

Higher Speeds:

Advances in signal processing and sensor technology to support faster rotational speeds while maintaining accuracy.

In summary, an encoder with 0.001° angular accuracy represents the pinnacle of precision measurement technology. It is indispensable in industries where even the slightest error can lead to significant consequences, enabling advancements in automation, robotics, and scientific research.