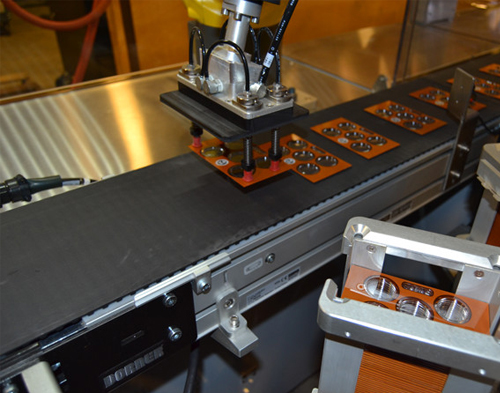

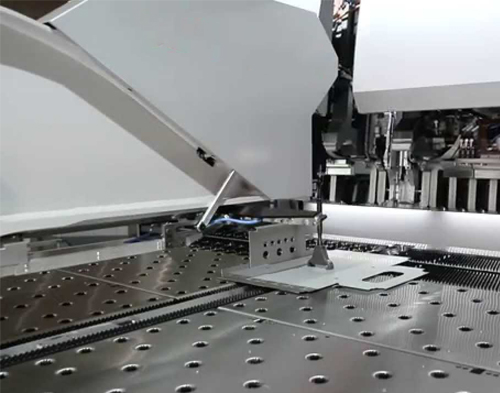

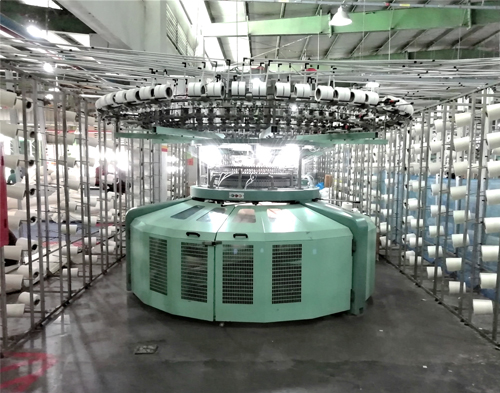

Encoder Applications

Encoders translate rotary or linear motion into a digital signal. The signals are sent to a controller, which monitors motion parameters such as speed, rate, direction, distance, or position. Since 2004, Gertech encoders have been applied for countless feedback requirements in most industries. When selecting the right encoder for your application, it's vital to understand the role of the encoder in your motion control system. To help with that, we’ve compiled a library of typical applications categorized by industry to help you find the right encoder for your motion control application.