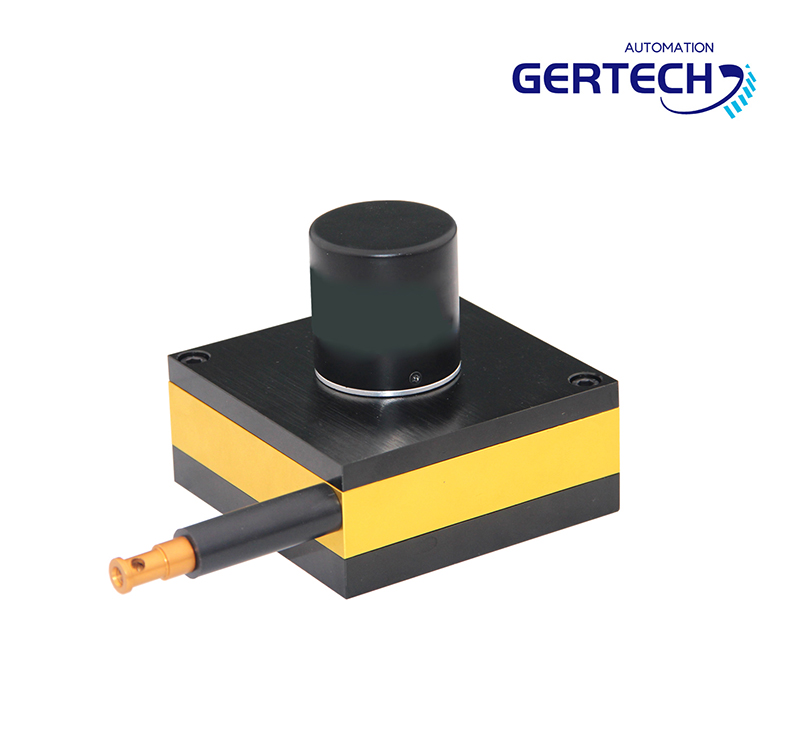

GS-SV48 Series 2500ppr Servo Motor Encoder

- Observes the mechanical motion of the actuator shaft—a change of position and the rate of change.

- Converts the mechanical input into an electrical impulse and transmits a series of such impulses as a quadrature signal to a controller.

To obtain velocity or angular displacement data, an encoder in a servo motor can be replaced with a potentiometer, a resolver, or a Hall effect transducer. However, the alternatives demonstrate inferior robustness, responsiveness, and reliability in most cases.

Advice on selection

Choosing a sensor to match a servomechanism requires exploring the specifics of the system where the assembly is supposed to be integrated, in particular:

- Type of propulsion. An application, where movements are along a straight-line trajectory, demands a linear detector. In machines performing angular displacements, the preferred type is rotary.

- Mounting method. The encoder body can incorporate a shaft, in which case it is assembled with the drive unit by means of a coupling. While enabling proper alignment, the coupling also isolates the sensing element from a drive unit, both mechanically and electrically.

An alternative is a hollow-shaft mounting arrangement, using a springed tether. The method eliminates the need for alignment and associated failures, but demands special measures to be taken to ensure electrical isolation from the drive unit. A third option is bearingless mount composed of a sensing element installed on the engine face and a magnetic element—on the shaft

Omron:

E6A2-CS3C, E6A2-CS3E, E6A2-CS5C, E6A2-CS5C,

E6A2-CW3C, E6A2-CW3E, E6A2-CW5C, E6A2-CWZ3C,

E6A2-CWZ3E, E6A2-CWZ5C; E6B2-CS3C, E6B2-CS3E, E6B2-CS5C, E6A2-CS5C,E6B2-CW3C, E6B2-CW3E, E6B2-CW5C, E6B2-CWZ3C,

E6B2-CWZ3E, E6B2-CBZ5C; E6C2-CS3C, E6C2-CS3E, E6C2-CS5C, E6C2-CS5C,E6C2-CW3C, E6C2-CW3E, E6C2-CW5C, E6C2-CWZ3C,

E6C2-CWZ3E, E6C2-CBZ5C;

Koyo: TRD-MX TRD-2E/1EH, TRD-2T, TRD-2TH, TRD-S, TRD-SH, TRD-N, TRD-NH, TRD-J TRD-GK, TRD-CH Series

Autonics: E30S, E40S, E40H,E50S, E50H, E60S, E60H SeriesPackaging Details

The rotary encoder is packed in standard export packaging or as required by buyers; FAQ:

About Delivery:

Leading time: Delivery can be within a week after full payment by DHL or other logics as per requested;

About Payment:

Payment can be made through bank transfer, west union and Paypal;

Quality Control:

Professional and experienced quality inspection team leaded by Mr. Hu, can ensure the quality of each product when it leaves the factory.Mr. Hu has more than 10 years experience in the industries of encoders,

About technique support:

Professional and experienced technique team leaded by Doctor Zhang, has accomplished many breakthroughs in the development of encoders, apart from normal incremental encoders, Gertech now has finished Profinet, EtherCAT, Modbus-TCP and Powe-rlink development;

Certificate:

CE,ISO9001,Rohs and KC is under process;

About Inquiry:

Any inquiry will be replied within 24 hours, and customer also can add what’s app or wechat for Instant messaging, our marketing team and technical team will offer professional service and suggestion;

Guarantee policy:

Gertech offers 1year warranty and life-long technical support;

We’re here to help. Our engineers and encoder experts will respond quickly to your toughest, most technical encoder questions.

Expedite options are available on many models. Contact us for details:Terry_Marketing@gertechsensors.com;