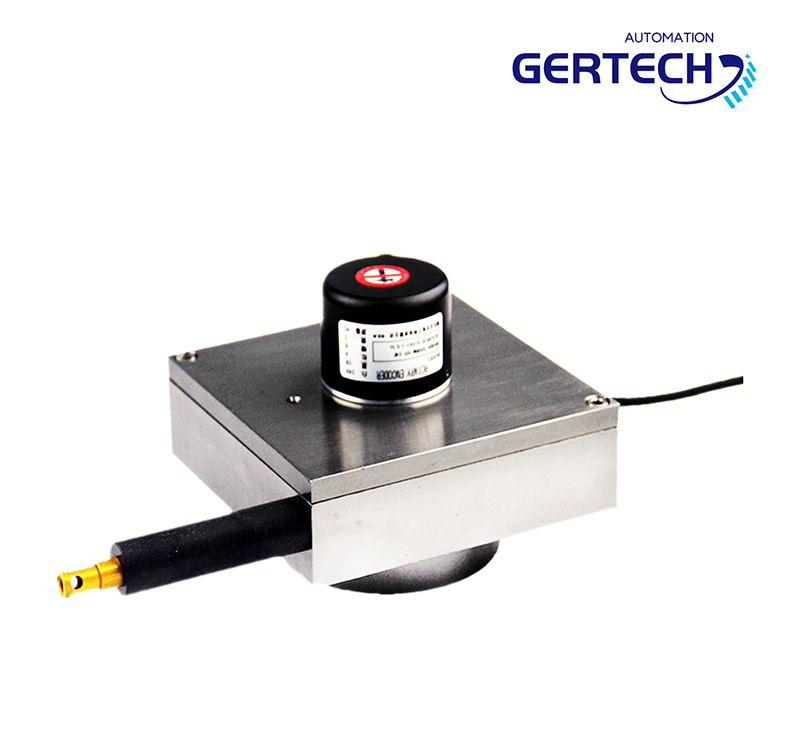

GI-D315 Series 0-10000mm Measurement Range Draw Wire Encoder

GI-D315 Series 0-10000mm Measurement Range Draw Wire Encoder

Draw wire sensors comprise a precision drum, wound with stainless steel cable and mounted to a rotary sensor. The sensor is usually an encoder or a potentiometer, depending on the performance required. As wire is pulled off the spring-loaded drum, it rotates the sensor creating a signal that is proportional to the length of wire extracted. This technique makes for a versatile linear sensor package.

Draw wire sensors offer a simple solution to measure linear speed and position. Utilizing a flexible cable, a spring-loaded spool, and a sensor (an optical encoder with incremental, absolute, analog or potentiometric output), draw wire sensors can precisely measure linear position. These sensors do not need precise linear guidance and are ideal for wet, dirty, or outdoor environments and applications where your measuring range travels through a harsh environment or hard-to-reach places. These include applications in iron, steel, sawmills and joineries.

Draw wire sensors are also known in the industry as cable transducers, cable-extension transducers, string potentiometers (“string pots”), draw wire transducers, yo-yo pots, linear position string pots, and string encoders.

GI-D315 Series encoder is a 0-10000mm measurement range high accuracy draw wire sensor. It provides optinal outputs: Analog-0-10v, 4 20mA; Incremental: NPN/PNP open collector, Push pull, Line Driver; Absolute:Biss, SSI, Modbus, CANopen, Profibus-DP, Profinet, EtherCAT, Parallel etc. Wire Rope Dia.:0.6mm, Linear Tolerance:±0.1%,The aluminum housing provides a reliable sensor ideal for industrial environments. Being both economical and compact, these are appropriate for a wide variety of applications.D315 Series provide extremely precise measurements because of the inherent accuracy of the encoders(both absolute and incremental encoders) and the rugged construction ensures reliable performance even under extreme conditions. Measurements are highly accurate, reliable and the systems have very long lifetimes without losing its inherent characteristics.

Certificates: CE,ROHS,KC,ISO9001

Leading time: Within a week after full payment; Delivery by DHL or other as per discussed;

▶Size:120mm x 120mm x 246mm;

▶Measurement Range: 0-10000mm;

▶Supply Voltage:5v,8-29v;

▶Output Format: Analog-0-10v, 4-20mA;

Incremental:NPN/PNP open collector, Push pull, Line Driver;

Absolute:Biss, SSI, Modbus, CANopen, Profibus-DP, Profinet, EtherCAT, Parallel etc.

▶Widely used in various fields of automatic control and measurement system,such as machinery manufacturing, shipping, textile, printing, aviation, military industry Testing machine, elevator, etc.

▶Vibration-resistant, corrosion-resistant, pollution-resistant;

| Product characteristics | ||

| Size: | 120mm x 120mm x 246mm | |

| Measurement Range: | 0-10000mm | |

| Electrical Data | ||

|

Output Format: |

Analog: 0-10v, 4-20mA;Incremental:NPN/PNP open collector, Push pull, Line Driver;Absolute:Biss, SSI, Modbus, CANopen, Profibus-DP, Profinet, EtherCAT, Parallel etc. | |

| Insulation resistance | Min 1000Ω | |

| Power | 2W | |

| Supply Voltage: | 5v,8-29v | |

| Mechanical Data | ||

| Accuracy | 0.2% | |

| Linear Tolerance | ±0.1% | |

| Wire Rope Dia. | 1.2mm | |

| Pull | 10N | |

| Pulling Speed | Max.300mm/s | |

| Working Life | Min.60000h | |

| Case Material | Metal | |

| Cable Length | 1m 2m or as per requested | |

| Environment Data | ||

| Working Temp. | -25~80℃ | |

| Storage Temp. | -30~80℃ | |

| Protection Grade | IP54 | |

| Dimensions |

Note:

▶Adopt elastic soft connection shall be applied between encoder shaft and output shaft of user end to avoid damage of encoder shaft system due to serial movement and run out of user shaft.

▶Please pay attention to the allowable axle load during installation.

▶Make Sure that the difference Between Axial Degree of encoder shaft and user output shaft shall be no more than 0.20mm, and the deviation angle with axis shall be less than 1.5 °.

▶Try to avoid knocking and falling collision during installation;

▶Do not connect the power line and the ground wire in reverse.

▶The GND wire shall be as thick as possible, generally larger than φ 3.

▶Output lines of encoder shall not be overlapped with each other to avoid damaging output circuit.

▶Signal line of encoder shall not be connected to DC power supply or AC current to avoid damaging output circuit.

▶The motor and other equipment connected to the encoder shall be well grounded without static electricity.

▶Shielded cable shall be used for wiring.

▶Before starting the machine, carefully check whether the wiring is correct.

▶During long-distance transmission, the signal attenuation factor shall be considered, and the output mode with low output impedance and strong anti-interference ability shall be selected.

▶Avoid using in strong electromagnetic wave environment.

Five steps let you know how to select your encoder:

FAQ:

1) How to select an encoder?

Before ordering encoders, you could clearly know which type of encoder you may need.

There are incremental encoder and absolute encoder, after this, our sale-service department would better work for you.

2) What specifications are requested before order an encoder?

Encoder type—————-solid shaft or hollow shaft encoder

External Diameter———-Min 25mm, MAX 100mm

Shaft Diameter—————Min shaft 4mm, Max shaft 45mm

Phase & Resolution———Min 20ppr, MAX 65536ppr

Circuit Output Mode——-you could choose NPN,PNP,Voltage, Push-pull,Line driver, etc

Power Supply Voltage——DC5V-30V

3) How to choose a right encoder by yourself ?

Exact Specification Description

Check The Installation Dimensions

Contact Supplier to get more details

4) How many pieces to start ?

The MOQ is 20pcs .Less quantity is also ok but the freight is higher.

5) Why choose “Gertech” Brand Encoder?

All encoders are designed and developed by our own engineer team since year 2004,and most of the electronic component of encoders are imported from overseas market. We own the Anti-static and no-dust workshopand our products pass the ISO9001. Never let our quality down,because quality is our culture.

6) How long is your lead time?

Short lead time—-3 days for samples,7-10days for mass production

7) what is your guarantee policy?

1year warranty and life-long technical support

8)What are the benefit if we become your agency ?

Special prices, Market protection and supporting.

9)What is the process to become Gertech agency?

Please send us enquiry,we will contact you as soon as possible.

10)What is your production capacity?

We produce 5000pcs every week.Now we are building second phrase production line.