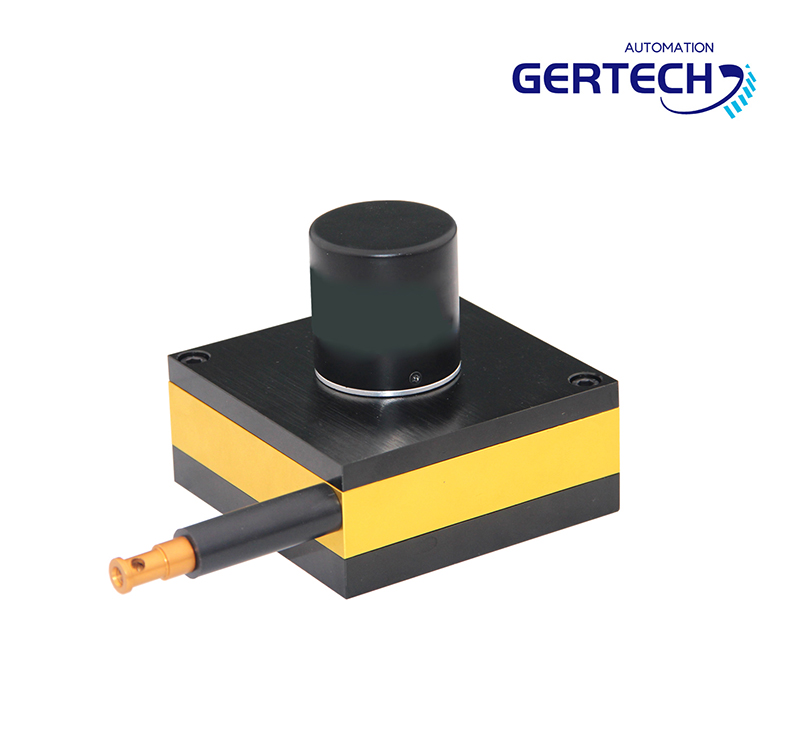

GI-D50 Series 0-2000mm Measurement Range Draw Wire Encoder

GI-D50 Series 0-2000mm Measurement Range Draw Wire Encoder

GI-D50 Series encoder is a 0-2000mm measurement range high accuracy draw wire sensor.

Analogue connection There are basically three different types of precision potentiometer used in draw-wire sensors from Micro-Epsilon: wire potentiometers, hybrid potentiometers and conductive plastic potentiometers. Conductive plastic or hybrid potentiometers are usually used for standard products. For high volume production applications, selection is made based on the required specifications for the application in order to achieve an optimum price/performance ratio for the customer. Digital connections Compared to analogue potentiometers, encoders have a significantly longer service life and better linearity. Incremental or absolute encoders are available depending on the application. Both types of encoder are fundamentally different from each other. Incremental encoders are used where the relative position displacement should be measured. In contrast, an absolute encoder assigns a unique position value to each measured value.It provides optinal outputs: Analog-0-10v, 4 20mA; Incremental: NPN/PNP open collector, Push pull, Line Driver; Absolute:Biss, SSI, Modbus, CANopen, Profibus-DP, Profinet, EtherCAT, Parallel etc. Wire Rope Dia.:0.6mm, Linear Tolerance:±0.1%,The aluminum housing provides a reliable sensor ideal for industrial environments. Being both economical and compact, these are appropriate for a wide variety of applications.D50 Series provide extremely precise measurements because of the inherent accuracy of the encoders(both absolute and incremental encoders) and the rugged construction ensures reliable performance even under extreme conditions. Measurements are highly accurate, reliable and the systems have very long lifetimes without losing its inherent characteristics.

The basic operating principle of a draw wire encoder is simple; a rotary encoder is coupled to a spring loaded-reel using a mechanical coupling device, internal to the housing of the reel. A cable is wound around the reel, usually a metal braid type. The braided cable is anchored to the drum of the reel and wrapped many times around it. The opposite end of the cable passes through an exit port of the draw wire encoder housing and is terminated with an anchoring device such as a clevis or loop to attach to the moving mechanism being measured. As the cable is pulled, the drum is rotated and the linear motion is translated into rotary motion, at which point the draw wire encoder encodes the information into an electric signal. In simplistic terms, the concept of a draw wire encoder can be likened to a fishing reel.

▶Size:63x63x78mm;

▶Measurement Range: 0-2000mm;

▶Supply Voltage:24v;

▶Output Format: Analog-0-10v, 4-20mA;

Incremental:NPN/PNP open collector, Push pull, Line Driver;

Absolute:Biss, SSI, Modbus, CANopen, Profibus-DP, Profinet, EtherCAT, Parallel etc.

▶Widely used in various fields of automatic control and measurement system,such as machinery manufacturing, shipping, textile, printing, aviation, military industry Testing machine, elevator, etc.

- Very compact design compared to the measuring range

- Telescopic measurement principle

- Very robust sensors

- Measuring wire can be deflected using deflection pulleys

| Product characteristics | ||

| Size: | 63x63x78mm | |

| Measurement Range: | 0-2000mm; | |

| Electrical Data | ||

|

Output Format: |

Analog: 0-10v, 4-20mA;Incremental:NPN/PNP open collector, Push pull, Line Driver;Absolute:Biss, SSI, Modbus, CANopen, Profibus-DP, Profinet, EtherCAT, Parallel etc. | |

| Insulation resistance | Min 1000Ω | |

| Power | 2W | |

| Supply Voltage: | 24v | |

| Mechanical Data | ||

| Accuracy | 0.2% | |

| Linear Tolerance | ±0.1% | |

| Wire Rope Dia. | 0.6mm | |

| Pull | Min.10N | |

| Pulling Speed | Max.100mm/s | |

| Working Life | Min.50000h | |

| Case Material | Metal | |

| Cable Length | 1m 2m or as per requested | |

| Environment Data | ||

| Working Temp. | -25~80℃ | |

| Storage Temp. | -30~80℃ | |

| Protection Grade | IP54 | |

| Dimensions |

Note:

▶Adopt elastic soft connection shall be applied between encoder shaft and output shaft of user end to avoid damage of encoder shaft system due to serial movement and run out of user shaft.

▶Please pay attention to the allowable axle load during installation.

▶Make Sure that the difference Between Axial Degree of encoder shaft and user output shaft shall be no more than 0.20mm, and the deviation angle with axis shall be less than 1.5 °.

▶Try to avoid knocking and falling collision during installation;

▶Do not connect the power line and the ground wire in reverse.

▶The GND wire shall be as thick as possible, generally larger than φ 3.

▶Output lines of encoder shall not be overlapped with each other to avoid damaging output circuit.

▶Signal line of encoder shall not be connected to DC power supply or AC current to avoid damaging output circuit.

▶The motor and other equipment connected to the encoder shall be well grounded without static electricity.

▶Shielded cable shall be used for wiring.

▶Before starting the machine, carefully check whether the wiring is correct.

▶During long-distance transmission, the signal attenuation factor shall be considered, and the output mode with low output impedance and strong anti-interference ability shall be selected.

▶Avoid using in strong electromagnetic wave environment.

Gertech Equivalent replace:

Omron:

E6A2-CS3C, E6A2-CS3E, E6A2-CS5C, E6A2-CS5C,

E6A2-CW3C, E6A2-CW3E, E6A2-CW5C, E6A2-CWZ3C,

E6A2-CWZ3E, E6A2-CWZ5C; E6B2-CS3C, E6B2-CS3E, E6B2-CS5C, E6A2-CS5C,E6B2-CW3C, E6B2-CW3E, E6B2-CW5C, E6B2-CWZ3C,

E6B2-CWZ3E, E6B2-CBZ5C; E6C2-CS3C, E6C2-CS3E, E6C2-CS5C, E6C2-CS5C,E6C2-CW3C, E6C2-CW3E, E6C2-CW5C, E6C2-CWZ3C,

E6C2-CWZ3E, E6C2-CBZ5C;

Koyo: TRD-MX TRD-2E/1EH, TRD-2T, TRD-2TH, TRD-S, TRD-SH, TRD-N, TRD-NH, TRD-J TRD-GK, TRD-CH Series

Autonics: E30S, E40S, E40H,E50S, E50H, E60S, E60H Series

Packaging Details

The rotary encoder is packed in standard export packaging or as required by buyers;

FAQ:

About Delivery:

Leading time: Delivery can be within a week after full payment by DHL or other logics as per requested;

About Payment:

Payment can be made through bank transfer, west union and Paypal;

Quality Control:

Professional and experienced quality inspection team leaded by Mr. Hu, can ensure the quality of each product when it leaves the factory.Mr. Hu has more than 10 years experience in the industries of encoders,

About technique support:

Professional and experienced technique team leaded by Doctor Zhang, has accomplished many breakthroughs in the development of encoders, apart from normal incremental encoders, Gertech now has finished Profinet, EtherCAT, Modbus-TCP and Powe-rlink development;

Certificate:

CE,ISO9001,Rohs and KC is under process;

About Inquiry:

Any inquiry will be replied within 24 hours, and customer also can add what’s app or wechat for Instant messaging, our marketing team and technical team will offer professional service and suggestion;

Guarantee policy:

Gertech offers 1year warranty and life-long technical support;

We’re here to help. Our engineers and encoder experts will respond quickly to your toughest, most technical encoder questions.

Expedite options are available on many models. Contact us for details:Terry_Marketing@gertechsensors.com;